Applications

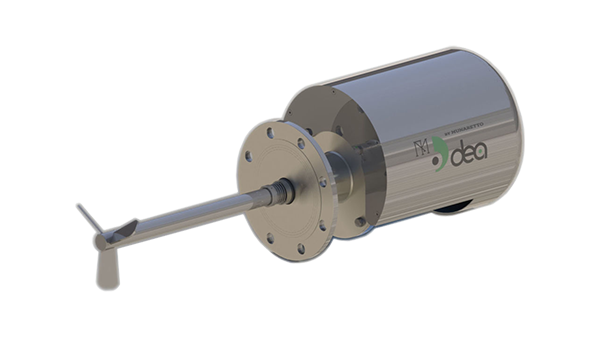

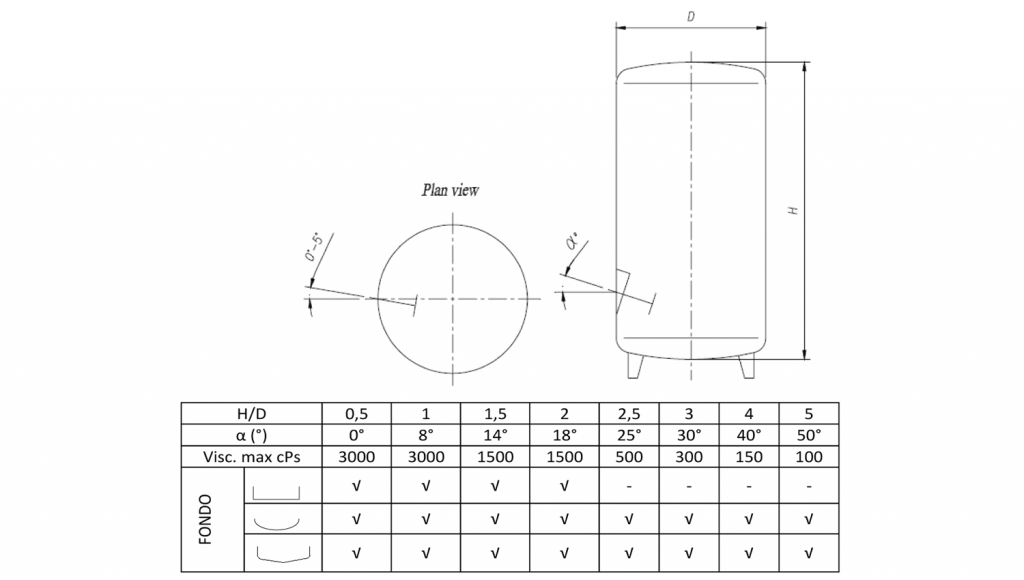

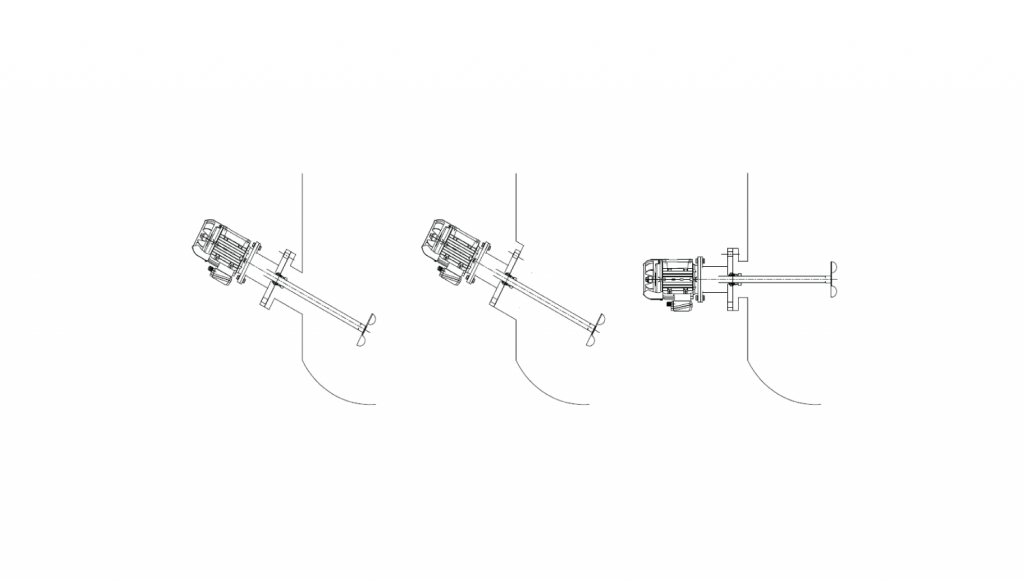

Compact, simple, practical, the MIX-F fixed stirrer is the ideal solution for the stirring of liquids inside pressurized or vacuum tanks. Each part has been sized and optimized to obtain the maximum efficiency and reliability under all conditions of use. Thanks to the range of standard motors available, the MIX-F fixed stirrer’s stirring characteristics can be customized in terms of power and rotation speed as required by the client’s system and product.

Examples of uses

Beverage industry: Wine, must, juice, beer, alcohol, syrup, etc. Food industry: Oil, sugar solutions, vinegar, mustard, etc. Residual fluid treatment: Spent oils, waste waters, coolants, etc. Chemical industry: Acids, detergents, inks, etc. Pharmaceutical industry: Emulsions, liquid soaps, etc. Paint industry: Paints, solvents, glues, etc.

Features

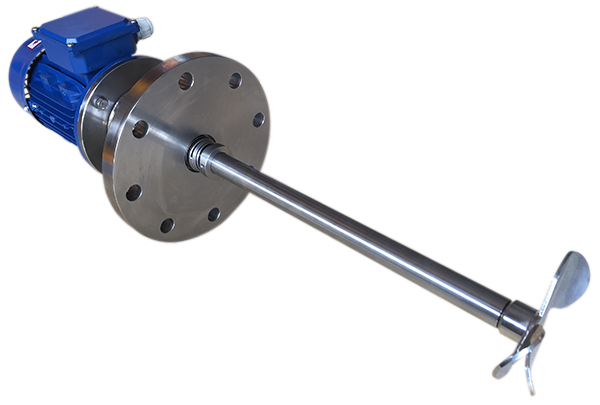

Every part of the MIX-F fixed stirrer in contact with the liquid is built in AISI 316 stainless steel. The impeller is rotated by the motor by means of a rigid connection. The standard mechanical seal provided is of the self-lubricating type with constructive materials that can be modified to suit the physical/chemical characteristics of the liquid processed (standard version envisions a STAINLESS STEEL/GRAPHITE connection).

In standard version, the MIX-F fixed stirrer’s impeller is of the “marine screw propeller” type that provokes a prevalent axial flow inside the tank in which the flow rate propelled is maximized while the shear forces imparted by the impeller to the liquid processed are minimized, in this way making the MIX-F particularly suited to all mixing processes in which the maximization of overall motion is crucial.

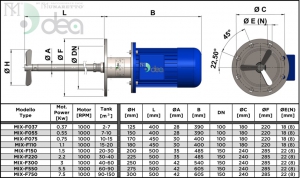

The MIX-F fixed stirrer is equipped with standard direct coupling IP 55 motors. For this reason, the power and rpm values indicated in the table below provide only one example of a vast range of possible combinations that can be obtained by merely substituting the motor as required and leaving all other stirrer parts as they are. Oversized electric motors can be mounted whenever particularly dense liquids must be processed and normal motors can be coupled to gear motors (with reduced propeller revolutions) whenever the type of processing requires greater delicacy.

Technical Features

Our mixers MIX-F are made with stainless steel AISI 316L for all of the food contact components.

The propeller is screwed on the shaft

The elctrical engine is a 6 poles – Flange B5 – IP55 – 50/60Hz – 230/400V

The mechanical seal is a single mechanical seal composed with stainless steel / graphite / EPDM

The connections are according the UNI-EN 1092-1 PN10-16 (ex UNI2278) Standard; editable on request

Options

The materials of the mechanical seal can be changed with harder materials

The elctrical engine can be changed with a 4-8 poles engine – Flange B5 – IP55 – 50/60Hz – 230/400V

The lenght of the shaft can be changed on custumer request

Our mixers can be equipped with a protective shroud