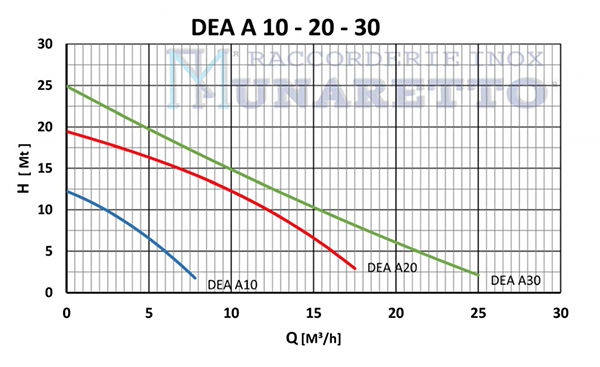

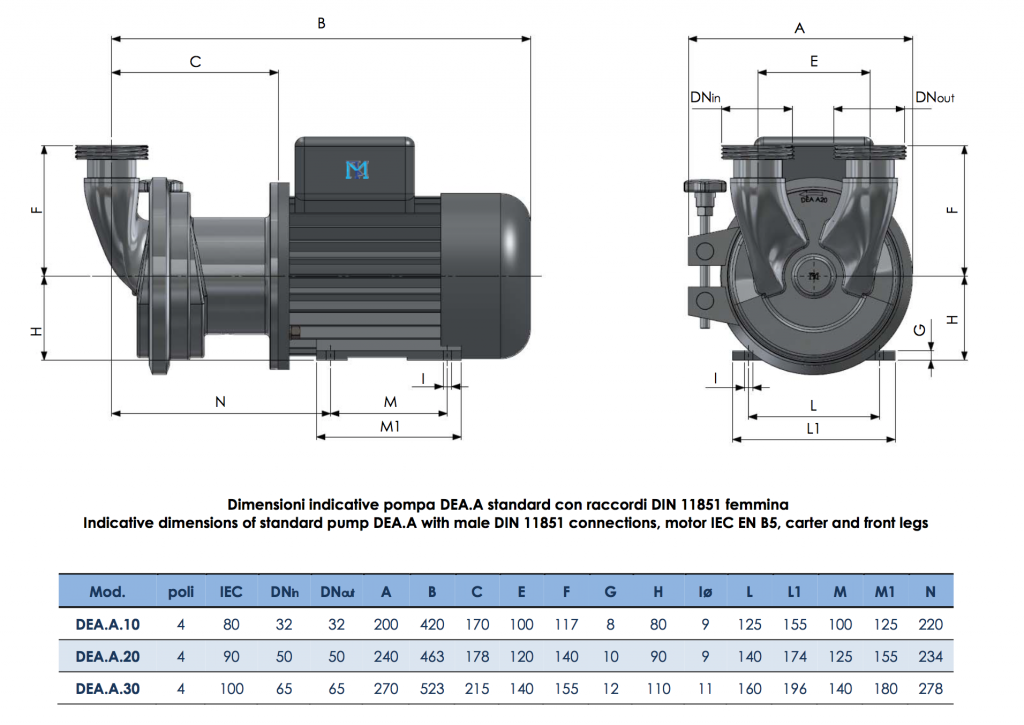

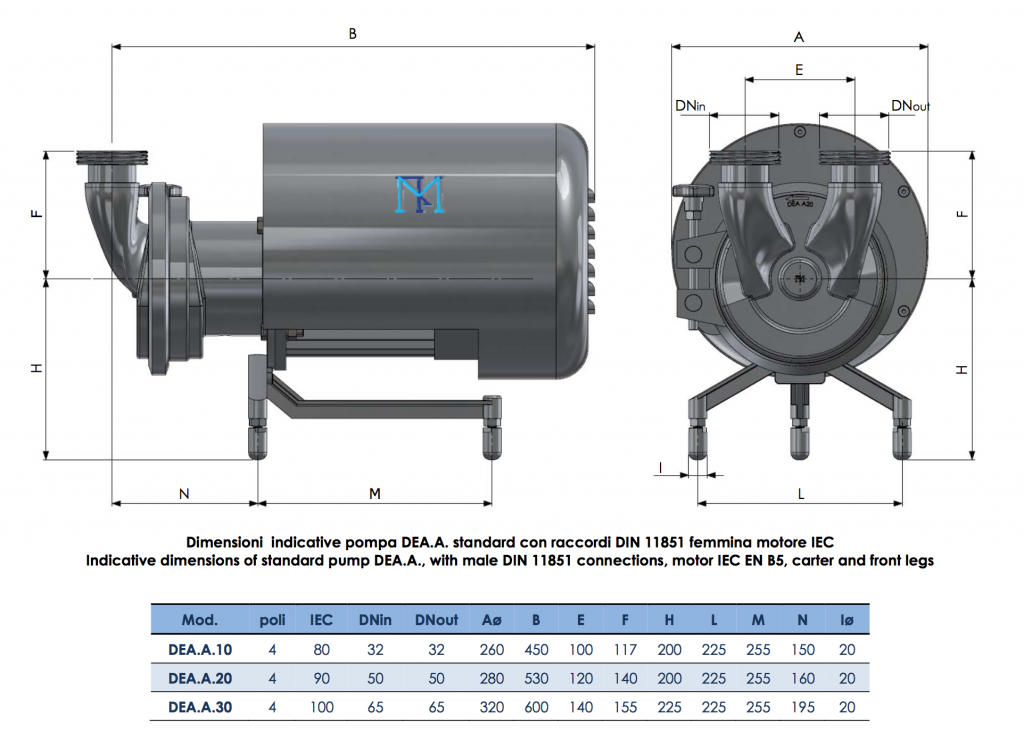

Our Self-Priming pumps DEA.A are made in stainless steel AISI 316 and they are devided by three sizes that correspond at three different flow rates, this help to use them in severals sectors.

They are different from our DEA.C range because they’re able to start the process automatically from the first rotation of the shaft and create the depression necessary to bring to them the liquids.

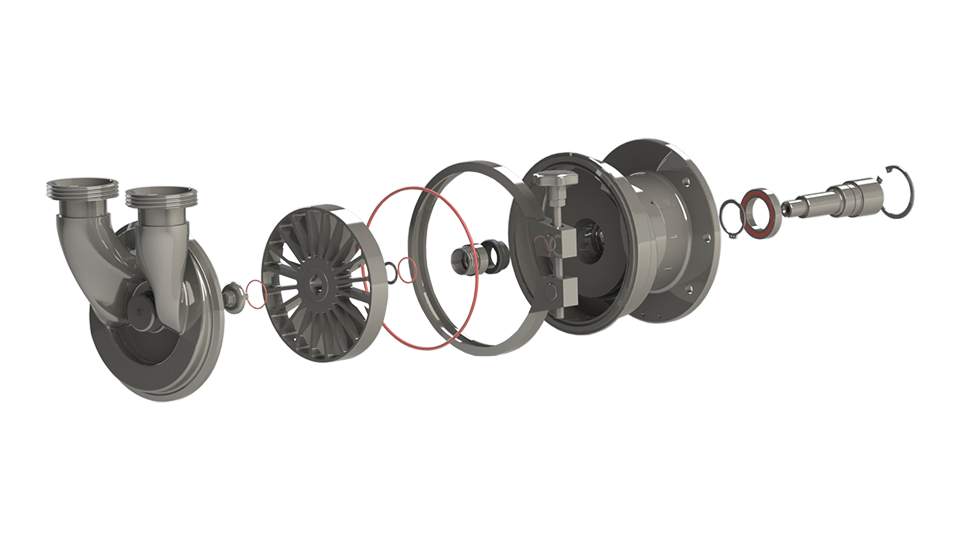

Technically, they are ausiliar side channel pumps for the self.priming process: initially, they need to be filled with the liquid (only fot the first use) and then it is not necessary anymore because the specific impeller’s profiles are designed especially to create the right depression in the aspiration area by reaching almost 2,5 times the depression that create a standard centrifugal pump.

The typical installation is upon the maximum level of the product because they’re able to self-priming by themselves. With this kind of installation, at the beginning, is created a turbolent circuit between the inlet area and the outlet area of the impeller that generates an air transport from the inlet manifold to the outlet manifold. Here the air is seprated by the decrease of the speed.

All the self-priming pumps are able to create the depression that is widely sufficient to garantee (during the pumping process) a correct pumps working.

The self-priming capacity allows to use these kind of pump without filling every time the aspiration duct (exept from the first use) and avoid the non-return valve (for this kind of use we have our DEA.CA range). Our DEA.A range are easily and usually used with the trolley version or in fix position to aspirate tanks or deep and far channel (until a certain distance, over that we need to calculate the effert to avoid any problems).